Visualize heat. Seal reliability. Scale globally.

Boyd (operating as LTI Holdings, Inc.) designs and manufactures the thermal, sealing, acoustic, and adhesive systems that protect the world's most critical technologies in transportation, aerospace, electronics, and medical markets.

Control heat, seal environments, manage noise, and bond structures

Four integrated pillars engineered for reliability in aerospace, electric vehicles, data centers, medical devices, and industrial technology.

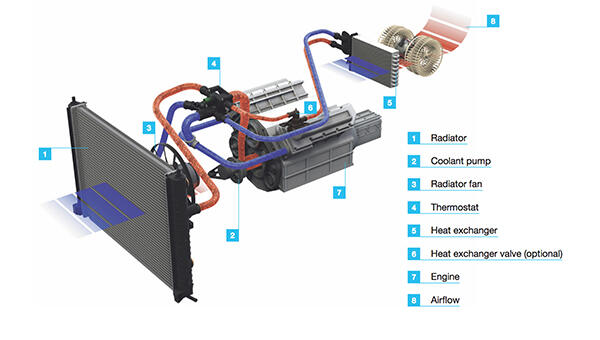

Optimize heat paths from component to ambient with complete liquid and air systems.

- Cold plates, heat exchangers, and two-phase systems

- Heat sinks, vapor chambers, and fans/blowers

- Thermal interface materials tuned for conductivity

Custom sealing architectures that defend against dust, fluid, and environmental extremes.

- Precision gaskets, O-rings, and enclosure seals

- Environmental and EMI shielding constructions

- Integrated thermal + sealing assemblies

Noise, vibration, and harshness control built into your system design.

- Damping, absorption, and isolation materials

- Cabin quieting and comfort enhancements

- Vibration isolation for mission-critical electronics

Engineered bonding systems that withstand thermal cycling and dynamic loads.

- Structural and pressure-sensitive adhesives

- Battery and electronics assembly bonding

- Coatings and tapes tailored to your substrate

Engineered for the world's most demanding programs

Switch between aerospace, e-mobility, electronics, medical, and industrial to see how we solve your heat and sealing challenges.

Flight-critical reliability

- Lightweight thermal solutions for avionics, radar, and power electronics

- Sealing systems validated for altitude, vibration, and chemical exposure

- EMI shielding and acoustic damping for cabin and mission systems

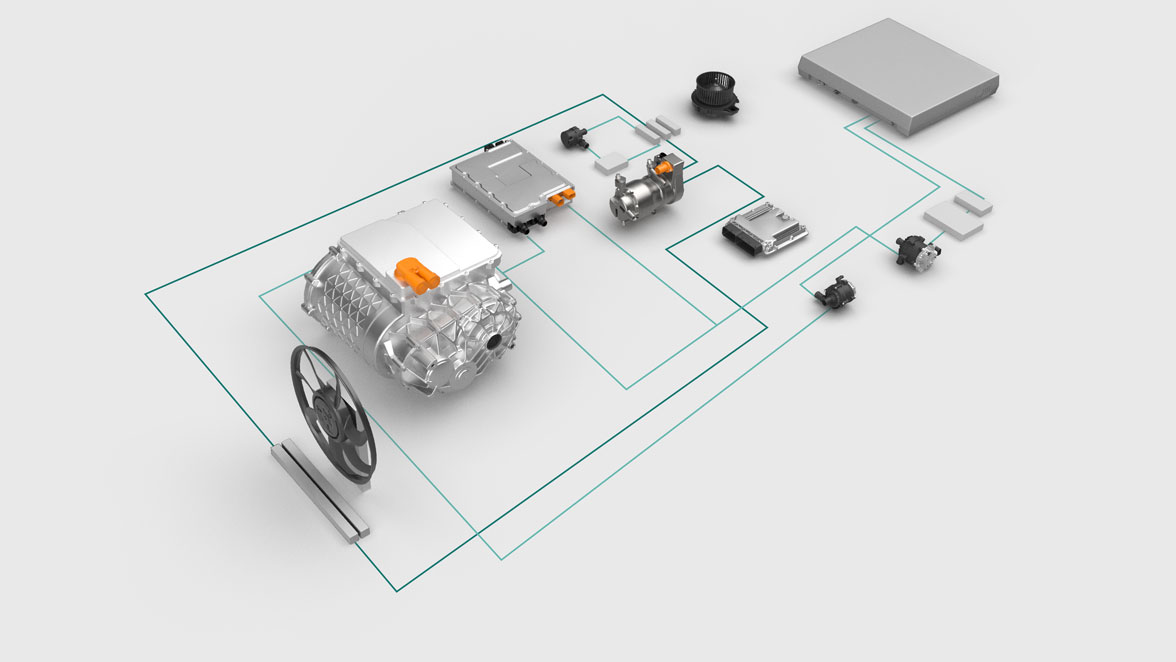

Battery-first engineering

- Liquid cold plates, TIMs, and gap fillers optimized for pack efficiency

- Fire, moisture, and debris sealing for battery enclosures

- NVH control for quiet, comfortable EV cabins

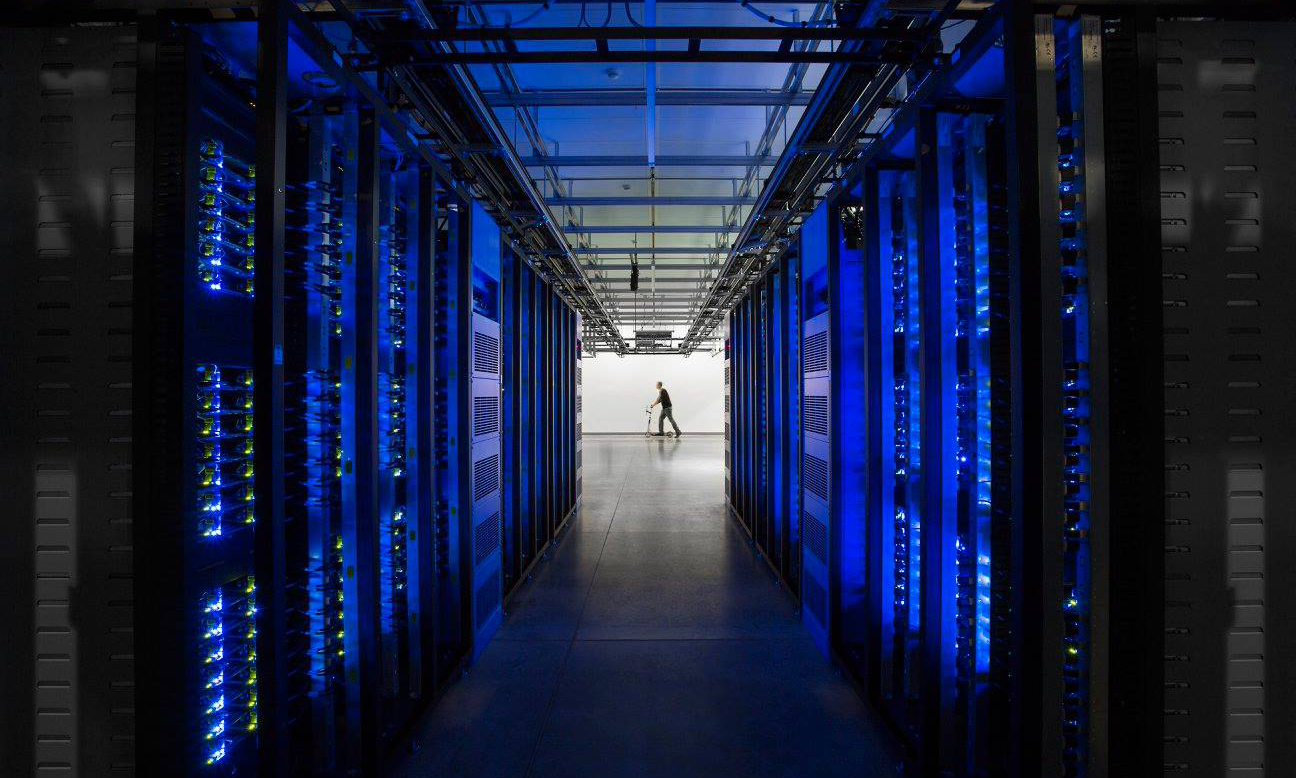

High-density computing readiness

- Rack-level liquid cooling, heat exchangers, and vapor chambers

- Thermal interface materials tuned for throughput and reliability

- EMI shielding and precision sealing for enclosures

Clinical-grade precision

- Thermal control for imaging, diagnostics, and patient monitoring

- Biocompatible sealing and bonding for sensitive devices

- Acoustic dampening for quieter patient experiences

Built for uptime

- Thermal assemblies that extend lifecycle of drives, controls, and power systems

- Sealing architectures that prevent ingress in harsh environments

- Noise and vibration isolation for heavy machinery and automation

See the heat path before you build

From simulation to production, we visualize and validate the complete heat path—leveraging CFD, material science, and system-level testing.

- Digital twins that accelerate design validation and shorten program timelines

- Integrated TIM + mechanical design for balanced pressure and conductivity

- Thermal, acoustic, and sealing co-design to eliminate late-stage rework

Local engineering, global manufacturing

Collaborate with regional design centers and build with globally consistent quality. Choose the hub closest to your program for faster ramp and resilient supply.

Active region: Americas

Download the Thermal Systems Playbook

Engineering guidance for balancing conductivity, pressure, and manufacturability in next-generation platforms. Includes checklists for EV battery packs, data centers, aerospace avionics, and medical devices.

Certified quality. Proven at scale.

See how we solve complex thermal and sealing challenges

EV Battery Thermal Path

Liquid-cooled cold plate design that balanced pressure drop, conductivity, and manufacturability for a high-volume EV program.

Read Case Study →

Data Center Density Gains

Rack-level cooling upgrade with vapor chambers and TIM stack-ups that improved thermal headroom without downtime.

View News →

Aerospace Sealing System

Lightweight sealing and EMI shielding solution qualified for high-vibration avionics environments.

Explore More →